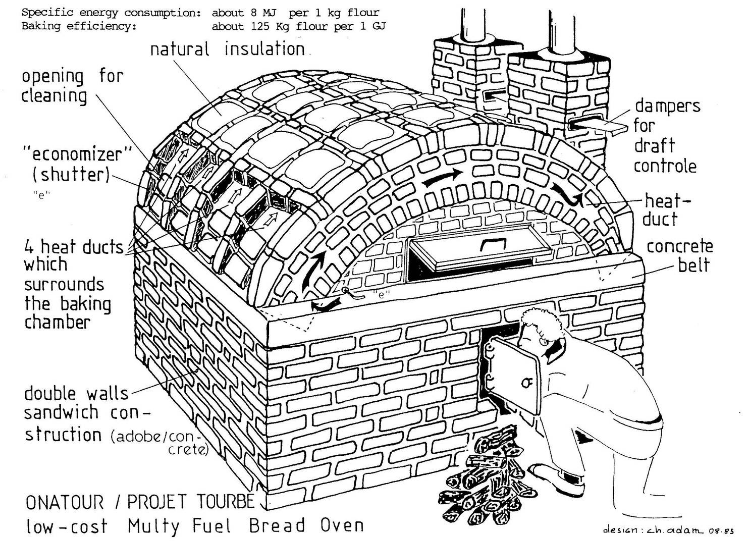

Burundi Multi Fuel Bread Oven (MFBO)

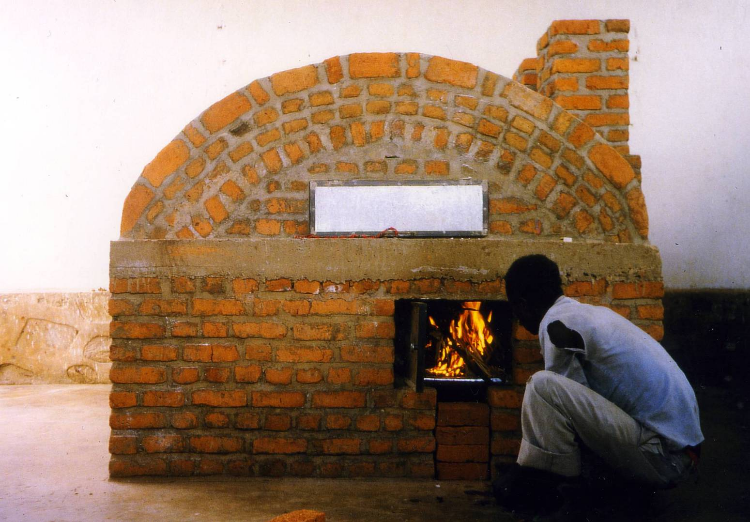

Photo: Multi Fuel Bread Oven at the University of Bujumbura , Design: Chris Adam (photos: adam, 1987)

Photo: Multi Fuel Bread Oven at the University of Bujumbura , Design: Chris Adam (photos: adam, 1987)

This Multi Fuel Bread Oven was developed for the Peat-II

Programme/ONATOUR

(Office National de la Tourbe) of US AID in Bujumbura, Burundi/ East Africa in 1986.

Peat is a kind of young coal and needs a stove or oven to be burned in a hot combustion chamber.

The bread ovens which existed in Burundi from the mostly Greek bakeries did not have a separation of the combustion chamber from the bread chamber. The bread was in direct contact with the hot volatiles from the fire. The taste of the aromatic smoke influenced the taste of the bread.

I concepted the separation of the ducts from the bread chamber. All kind of waste fuel like leaves, agricultural residues, wood or

peat could now be use as a fuel. This was the reason to name the bread oven MFBO (Multi Fuel Bread Oven).

This is a modern designed bread oven with outer dimensions of 2m x 2m x 1,5m and a bread chamber of 1,2m x 1,2m.

A STOVE TEAM (see photo below) was established at ONATOUR (Office National de la Tourbe/ National Peat Office) which build the MFBO at bakeries, university canteens, school, hospitals and prisons.

The marketing concept was in that way that if the institution or private owner ordered or contracted 10 tons of peat, he got supplied with a MFBO. This concepted worked well.

The main characteristics are:

* the smoke (hot flue gases) is separated from the bread chamber, so smelling fuels (peat, coal, agricultural waste, etc.) can also be used.

The Bread Oven can be used continuously because it has external heating (separated) for the bread chamber.

* the hot flue gases are surrounding the bread chamber- resulting in a high efficiency of the oven.

* Work material are mainly locally made bricks, a strong cement belt keeps the oven together.

* we have a good natural insulation with hollow space.

* specific energy consumption about: 8Mj per 1Kg flour; Baking efficiency about: 125kg flour per 1 Gj.

(1kg of wood is about 16MJoule; 62kg of wood = 1Gj.) The consumption of peat per 8 bread making hours is about 50-75kg (heat value ~12.000 Kj/kg).

The MFBO was build within two weeks by the STOVE TEAM/ BAKERY TEAM. During the first week the strong cement belt was cast. The STOVE TEAM build an additional oven during the second week and finished the first oven in the 3rd week.

Reference gtz: (page

39/166)

www.gtz.de/dokumente/bib/97-0616c.pdf

http://www.hedon.info/View+Stove?itemId=10239

If you want to add a comment, go the the 3rd page "adam-retort kiln" to add a comment, thanks...