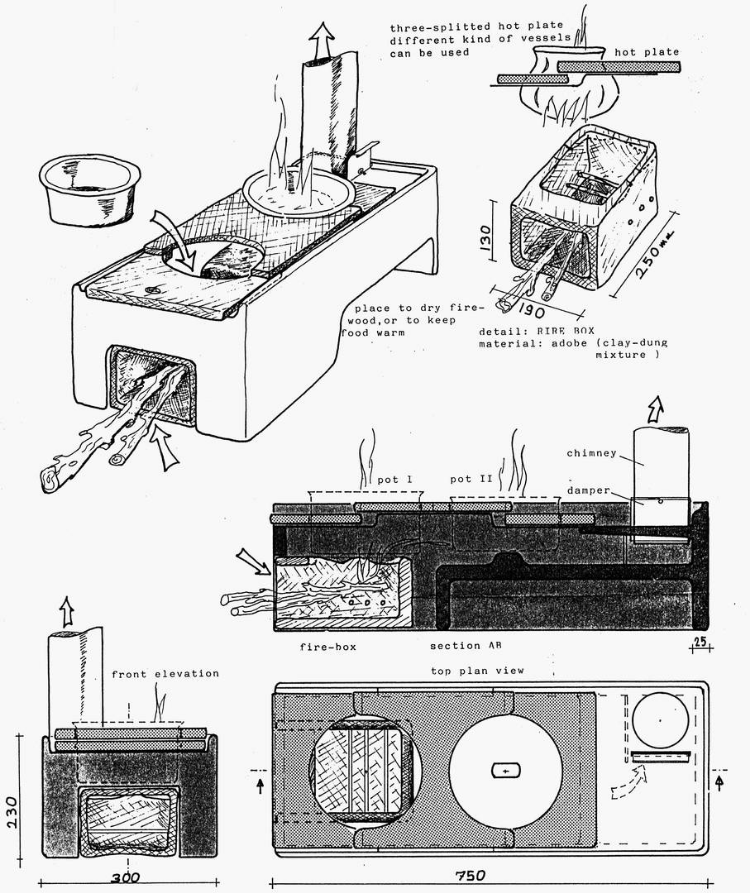

PDI Family Cooker (Pakistan Design Institute)

Introduction

The story started like this in1982. I was working in the product section of PDI (Pakistan Design Institute in Karachi, promoted by the Swiss Government/DEZA-DEH) and i discovered some paper or pamhlet about the Family Cooker from Eindhoven which was developed by Mr J. Overhaart (and the Woodburning Stove group) at the Eindhoven University in the eighties. The paper claimed that the stove would save about 50% fuel and that it was a novelty for Development Countries. Introduced this concept to our management and we decided to work in this field of fuel saving stoves. However it took our trained model maker one (!) week to make a copy of the Eindhoven Family Cooker (FC), (see photo below).

The FC had two other disadvantages: 1st the wood had to be chopped into very short pieces (5cm(?) length).

2. The second pot did not get hot at all.

I started to think how this concept of the FC could have been adapted to Pakistan and rural areas and I designed the PDI-FC. To overcome one disadvantage of cutting the wood into short pieces, i invented the covered wood box. For getting a hot combustion i designed a hot fire box made out of a clay-adobe mixture. Unfortunately i started this work on fuel saving stoves just a month before my contract was ended at PDI.

Returning to IPAT-Institute at the Technical University of Berlin, i designed in 1984 the New PDI-Family Cooker (New PDI-FC) on the basis of the existing PDC-Family Cooker.

CONCEPT:

This low-mass cooking stove achieves more that 30% fuel saving, compared to a three stone open fire, because the heated surface of the cooking pots is larger than the part of the pots which is cooled

by the surrounding air. Both cooking pots are sunk inside the stove plate.

The effect of a hay box can be used for cooking, after closing the chimney damper when the stove is hot.

The “percentage heat utilization (PHU)” is about 29% and it can be increased to 36% if the stove sides are insulated with mineral wool. The temperature of the flue gazes entering the chimney are about 98C°.

Photo right: separate fire box

The separate fire box (mad out of clay material) prevents that the stove walls get too hot and that they get cracks. The hot fire box enables a clean burning of the fuel. The heat in the fire box

is concentrated upwards to the pot.

The hot plate is made from cast iron, or from reinforced cement (Ferro cement (with alumina-cement)), or made out of metal sheet (especially if some room heating is preferable)

Advantages of the NEW PDI-Family Cooker compared with the PDI-Family Cooker:

· Large pieces of firewood can be used

· The fire can be seen from outside and it can be better controlled

· Fuel saving more than 30% because of partly sunk cooking pots. (Up to 50% of fuel saving can be expected if the hay box effect is being used).

· The hot plate comes in 3 sections for the use of different sizes and shapes of the pot

· This is a transportable low-mass stove which can be made out of sheets (metal or fibre cement), or the stove chassis can be cast in cement, ceramic or clay by local craftsmen.

A damper is fitted before the chimney. The damper should be closed after the fuel burned down, to keep the heat inside the stove and to use the stove as a hay box.

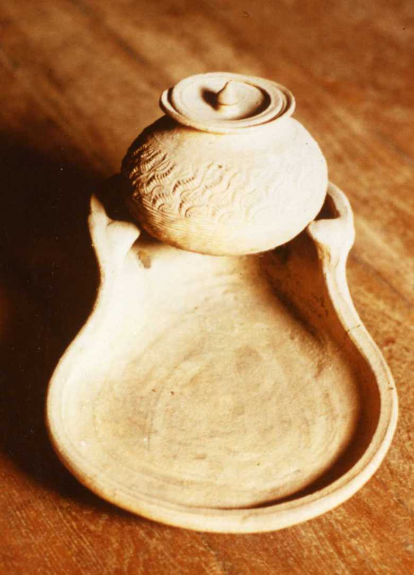

3 Photos: Its not "us" who were the first to think how to burn wood with an improved stove!

Different cultures have developed same principles and solutions for fuel saving stoves.

Photos taken in 1982 from improved wood stoves already existing in Pakistan, Philippines/CEBU and Thailand (Tim Thompson Museum BKK)

This PDi-Family Cooker from 1982 has some similarities with the famous PHILIPS-CHULA which won several prizes in 2009, isn''

http://www.idsa.org/content/content1/chulha-low-smoke-biomass-stove (link broken)

https://www.90yearsofdesign.philips.com/awards

If you want to add a comment, go the the 3rd page "adam-retort kiln" to add a comment, thanks...